Yingde Gases has more than 100 on-site gas plants, three Logistics distribution centers and operation centers and more than 500 cryogenic liquid tankers all over the country, covering thousands of liquid end customers in metal processing, chemical industry, materials, electronics, food and beverage industries, providing high-quality industrial gas products and services such as liquid oxygen, liquid nitrogen, liquid argon, etc. At present, the daily liquid production capacity of Yingde Gases exceeds 15,000 tons, with a yearly distribution mileage of 1000 laps around the earth!

Yingde Gases always puts our customers’ needs first. Yingde Gases’ professional service team provides customers with efficient, professional and reliable products and services ranging from preliminary business consultation, formulation of technological solutions, liquid distribution services and after-sales services, being committed to fully safeguarding our customers' production needs.

Planned delivery: 100% punctual delivery within 48 hours

Urgent delivery: Delivery is arranged within 24 hours based on the nearest source of goods and nearest vehicles

The MiniBulk business unit has introduced a completely new set of options to clients traditionally receiving gas in cylinders, cylinder packs, Dewar flasks and other containers, offering an uninterrupted supply of cryogenic, high-purity nitrogen, oxygen, argon, and carbon dioxide.

The MiniBulk system includes a small storage tank installed on-site, and a small tanker truck specifically built for holding cryogenic gases. A cryogenic storage tank replaces the cylinders previously kept at production facilities, freeing the client from the hassle of constantly having to switch out their bottled gas. The skid assembly design of the small storage tank saves space, and can be installed on level ground, offering customers a quick, economical, lossless, and 100% reliable gas supply experience.

The MiniBulk service network includes a support team with extensive experience in applied technologies, external and internal sales teams, and a client services engineering team stationed at location, not only devising gas supply solutions, building on-site filling stations, and handling all logistics for shipping and delivering gas, but also providing added-value services related to the use of industrial gases.

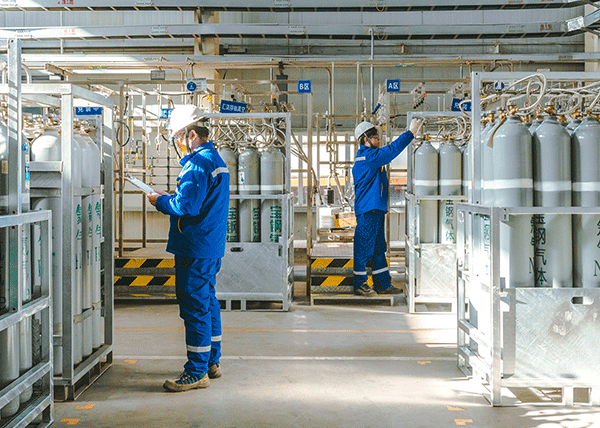

Yingde Gases operates multiple industrial cylinder gas production facilities, manufacturing bottled industrial gases including oxygen, nitrogen, argon, and helium. Utilizing automated filling processes, stringent quality control, and a scientific cylinder management system, we ensure stable purity and secure, efficient supply.

Leveraging its expertise in industrial gases, Yingde Gases provides hydrogen supply in various packaging formats to support the national economy. It offers comprehensive solutions for the chemical, electronics, and metallurgical industries, empowering business growth.

Yingde Gases possesses over 50 certificates for reference materials, along with internationally recognized gas blending technology and a rigorous quality traceability system. This ensures stable gas composition and precise data, enabling customers to achieve accurate testing and efficient production. Our solutions meet the demands of environmental protection, chemical engineering, testing, healthcare, industrial analysis, and other sectors.